SD MECATEC Inc.What Do We Do?

Founded in 1997 as SM TECH, Incorporated in 2010 as SD MECATEC 9,900㎡, 4 FACTORIES & 1 OFFICE BUILDING in KOREARigorous Quality Control Carried Out by Dedicated Quality Department

Founded in 1997 as SM TECH, Incorporated in 2010 as SD MECATEC 9,900㎡, 4 FACTORIES & 1 OFFICE BUILDING in KOREARigorous Quality Control Carried Out by Dedicated Quality Department

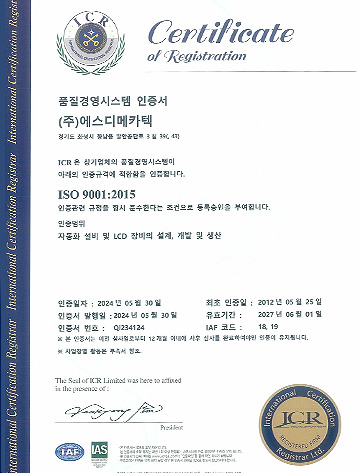

Numerous Patents & Quality Certifications Prioritizing Quality & Customer Satisfaction

SD MECATEC holds 11 patents and is a trustworthy company with well-Known quality certifications, including SSQ, ISO 9001, ISO 140001, CE, etc.

Inno-Biz

Certification of SEMES Supplier Quality

EC Deciartaion of Conformity

ISO9001

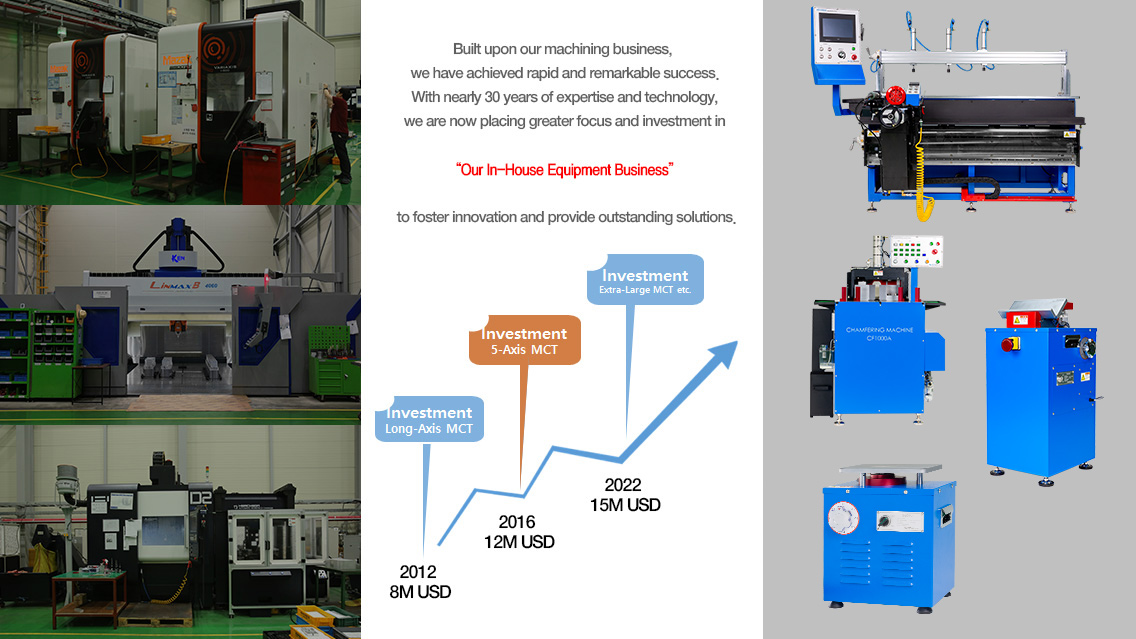

Cutting-Edge Preparation Aligned with the Forth Industrial Revolutionn

Through 5-Axis CNC Machining, Workpiece Automatic Exchange Systems, and Smart Factory Integration, We Have Achieved Maximum Efficiency in Production Automation. This Ensures Cost Reduction & Maximizes Production Output, Securing a Competitive Edge for the Future

Extensive CNC Machining Capacity : 62 CNC Machines

5-Axis CNC Machining: 11 Machines 3-Axis CNC Machining: 51 Machines Tool Grinding/Measuring : 4 Instruments

With Numerous CNC Centers and Tool Grinder, We Produce Custom and Special Tools In-House, Enabling Cost Reduction and Faster Lead Times

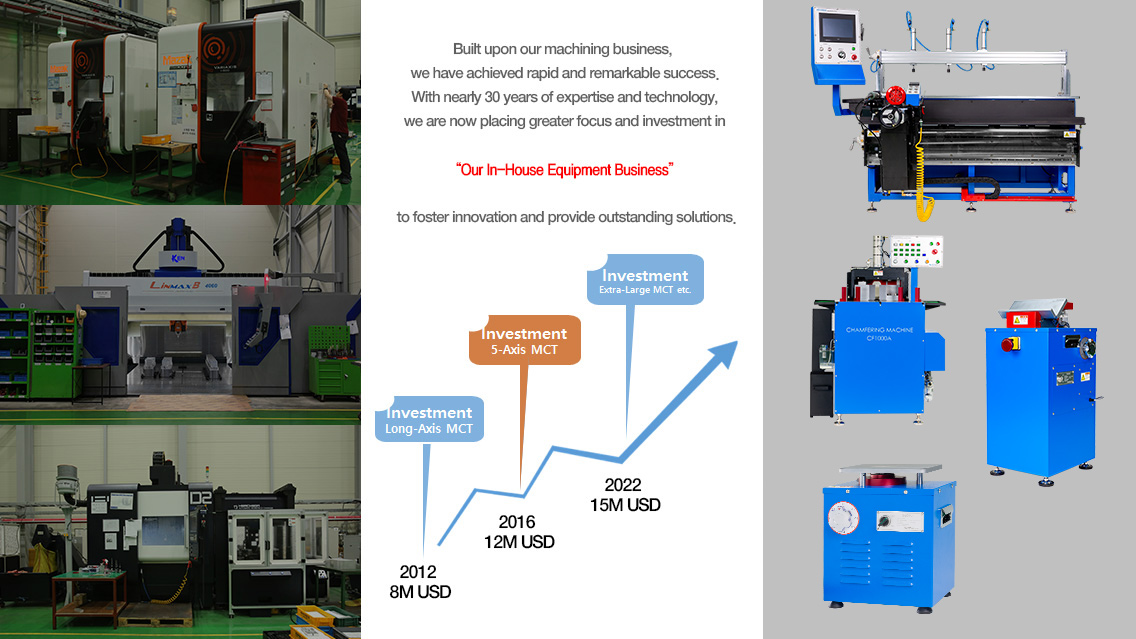

SD MECATEC In-House Innovation

Servo motors allow the X / Z axis to move quickly & easily to the machining point Simultaneous drilling & Tapping with no tool change required Simple controls allow beginners to operate easily Significantly more affordable than CNC machining centers offering excellent value Safety & easy maintenance ensured by proven components

SD MECATEC In-House Innovation

Pre-chamfering allows for reduced processes and setup time Reliable program and simplified operations for unskilled users Ideal for reducing process costs and labor expenses Delivers surface finish quality superior to milling machines Easy to chamfer steel and aluminum, capable of chamfer size from 1C to 20C

SD MECATEC In-House Innovation

End mill chamfering machine for the first time – “BURR FREE” Effortless operation, designed for unskilled users Easy control of chamfer size and tool position using dials Extended tool life and chip management to prevent scattering Easy to chamfer STS, Steel, Aluminum, Resins, and more, regardless of length

SD MECATEC In-House Innovation

End Mill Chamfering Machine for the First Time – “BURR FREE” Effortless operation, designed for unskilled users Easy control of chamfer size and tool position using dials Easy tool change, reducing change time by more than 50% Easy to chamfer STS, Steel, Aluminum, Resins, and more, regardless of length